Collaboration on energy efficient cold magnets

The European Regional Structural Fund Programme for Småland and Islands and Region Kronoberg have decided to contribute to a new collaboration project with Uppsala University, Linnaeus University and a cluster of technology companies in the province of Småland. The project of SEK 19 million aims to develop energy efficient superconducting magnets where research and technical development can be combined to create global competitiveness.

We are on the cusp of a technological transition from “warm” normal conducting magnets to “cold” superconducting magnets. Normal conducting warm magnets use water-cooled or air-cooled cables, while superconducting cold magnets use a superconducting effect created when cooling using liquid helium. These superconducting magnets, which place high demands on design and manufacturing, enable much higher current density than normal conducting magnets. This allows them to be much smaller while achieving a higher magnetic field with a reduction in total energy consumption.

Mature technology

To enable development and manufacturing of these magnets requires collaboration in innovation between research and industry. The project Disseminating technology for cold magnets to provide access to a wider international market, which has now received financial support from the European Regional Development Fund (ERDF) and Region Kronoberg, hopes to combine expertise within research, business, technology and innovation to compete on a global market.

The theory and technologies behind superconducting magnets are relatively mature, but to date no manufacturing has begun in Sweden. The project will use new manufacturing technologies to produce an innovative new type of magnetic design (canted cosine-theta design) that can be used to control charged particles, like electrons and protons. By adding some technology and business model skills development, the participating companies in Småland have the necessary basic expertise to be able to learn to manufacture superconducting magnets. Uppsala University and Linnaeus University will provide this skills development.

Need each other

and Astronomy and the head of the project.

Photo: Mikael Wallerstedt

The project participants complement each other, and they supply services and manufacture parts relevant for the project, which is a prerequisite for growth and skills development.

“The project is intended to expand knowledge and skill sets and improve the ability to innovate in a grouping of companies in Småland, which will eventually benefit the entire business community throughout the Kronoberg region. Uppsala University, Linnaeus University and these companies in Småland combine their unique areas of expertise,” says Olof Karis, professor at the Department of Physics and Astronomy and the head of the project. “We need industrial partners to allow us to develop research. And companies need us for their own skills development.”

A prototype is the first step

The project participants believe that superconducting magnets will become increasingly important tools within science, medicine and industry. The first step toward this goal is to manufacture a prototype for CERN in Switzerland using methods and technologies that are more environmentally friendly than used by currently established manufacturing.

“CERN plans to use these superconducting magnets to upgrade their large accelerator. Other large research facilities are interested in these magnets. In the future, we can also use them for such applications as cancer therapies,” says Roger Ruber, researcher at the Department of Physics and Astronomy and in charge of technology in the project.

The hope is that the project will provide the first complete development of these types of magnets in Sweden.

“We are offering industry the opportunity to master this essential technology,” says Olof Karis. “Superconducting magnets definitely have major potential in leading to a paradigm shift for applications needing large magnets. They will also be a more environmentally friendly alternative.”

Anna Malmberg

Collaborative partners in the project

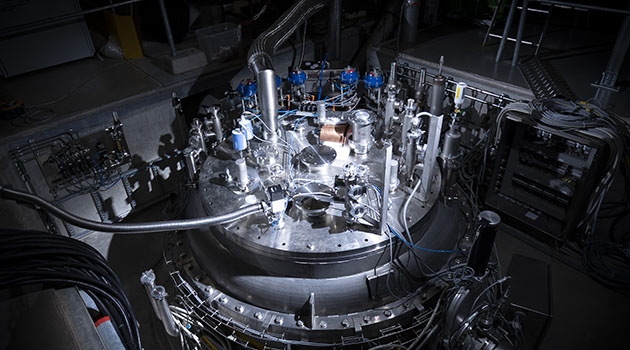

Uppsala University is providing FREIA Laboratory as research infrastructure of national interest along with technical resources and staff for activities intersecting basic research and collaboration with industry. FREIA Laboratory will develop the magnet and test it in its superconducting state at –270 degrees Celsius to confirm its characteristics.

Linnaeus University is very active within business and economics and within technology. The Department of Mechanical Engineering specialises in product development, where they are developing new theories within product development and product design. Within business and economics, they study entrepreneurship, management and organisation. The Department of Accounting and Logistics studies how to make processes in the supply chain more effective.

Scanditronix Magnet AB specialises in developing and manufacturing normal conducting warm electromagnets for use in particle accelerators. The magnets are used to control and influence particle beams in the accelerators. Scanditronix Magnet’s task will be to take care of the procurement, manufacture and installation of all the parts for the superconducting magnet.

Ryd-Verken AB specialises in tool manufacturing, advanced processing and pressing. The company has large, advanced processing machines needed for this project. Ryd-Verken will perform the advance processing of the metre-long magnet spindles with three-dimensional grooves for superconducting cables.

Vattenskärningsteknik i Vislanda AB specialises in abrasive water jet cutting. Since its founding, the company has continually invested in the latest technology and equipment for the highest possible precision, something that is essential for meeting the strict specifications of the project.